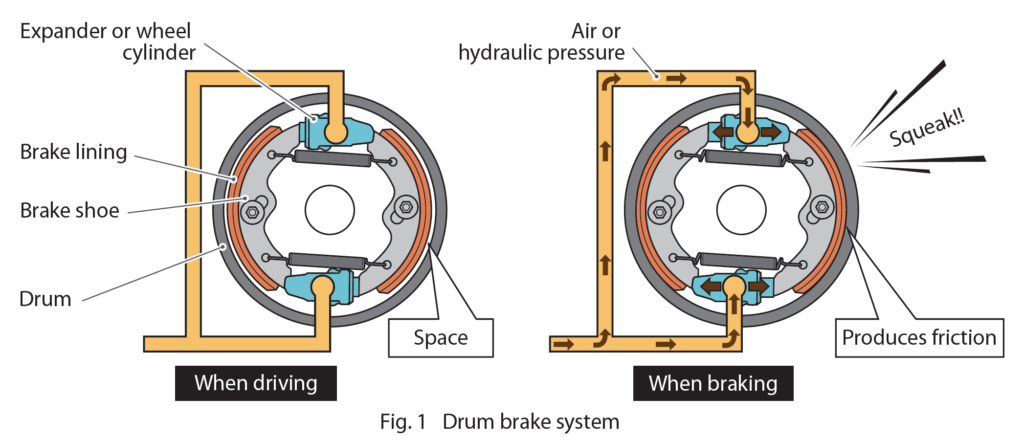

During braking, brake linings apply frictional forces to a cylindrical drum attached to the wheel to reduce its speed and enhance control of the vehicle.

Brake systems come in two types: drum brake and disc brake. The former consists of a cylindrical brake drum and brake linings, and the latter consists of a brake disc and brake pads. In this document, we describe brake linings that are used in drum brakes.

Drum brake

Disc brake

2. Construction

The brake shoe expands by air pressure (expander) or hydraulic pressure (wheel cylinder) to press the brake linings against the drum, producing a frictional force which reduces and controls the speed of the vehicle.

Brake lining

The brake linings are assembled onto the brake shoe. They press against the drum to produce friction.

Brake shoe

These are widened by the expander, and cause the brake linings to produce friction.

Brake drum

The brake drum rotates with the wheel. The brake linings are pressed against this drum to brake and stop the vehicle.

Expander or wheel cylinder

This component presses the brake shoe wide by air or hydraulic pressure.

3. Brake types & features

Brake linings come in the following different types depending on their unit of supply.

Type

Images

Unit of Supply

Single brake lining

This contains one brake lining.

Brake lining kit

This kit contains two or four brake linings and attaching rivets.

Brake shoe assembly

This is an assembly where the brake linings are attached to the brake shoe.

4. Differences between genuine and aftermarket parts

Genuine parts have been developed for specific Hino models and applications to fulfill a diverse range of requirements for specific Hino models and operating conditions. Aftermarket parts place emphasis on cost, do not provide the levels of performance, life cycle, or quality found in genuine parts, and may not be a good match for Hino model or operating environment.

Comparison of performance of genuine and aftermarket parts.

Item

Genuine

Aftermarket parts

1. Heat resistance

Is resistant to heat (which makes it less prone to degradation or sudden deterioration in performance)

Is less resistant to heat

2. Stability of braking force

Stable, because it matches the model and operating environment.

May not be a good match for Hino model or operating environment.

3. Life cycle

Less wear <Longer life cycle>

More wear <Shorter life cycle>

4. Screeching

Less prone to screeching

More prone to screeching.

5. Drum aggressiveness

Causes no drum damage.

Causes drum damage.

All Hino genuine brake linings comply with European safety law ECE.

They have been optimized for Hino vehicles based on Hino standards which are more stringent than ECE standards.

The performance data of aftermarket parts shown above were obtained from a limited sampling of parts and do not represent the performance of all aftermarket parts.

5. The importance of maintenance

Braking performance drops significantly when brake linings wear down beyond their usage limit. Additionally, if the rivet heads and shoe become exposed, the inside of the drum and brake components can be damaged, which can lead to accidents and breakdowns. Because the rate at which brake linings wear out will depend on the driving environment and cargo load, we recommend that you inspect brake lining wear on a monthly basis or every 5,000 km, in addition to checking the amount of remaining lining before you begin your day and how well the brake performs during the day. In particular, if you notice any of the phenomena or problems below, you must immediately inspect and/or replace your linings:

- Judder – Juddering vibrations occur when you apply the brakes.

- Faulty braking performance – Brake locking, insufficient or excessive braking effectiveness, or other braking instabilities.

- One-sided braking – Difference in the effectiveness of right and left brakes, causing the vehicle to pull to one side.

- Fade – The brake lining gets too hot due to excessive braking, and the heat causes a loss in frictional force.

<Remarks>Unusual sounds coming from around the brake area when you apply the brakes can be a sign of faulty brake connection which requires inspection as soon as possible.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.